Coated Glass

Coated Glass

Heat Reflective GlassKSL2014

Heat reflective glass, which presents the beautiful appearance of a building and protects personal privacy, can present the outer walls of a building in a more elegant and stylish manner with various colors and it has the effect of blocking the hot solar heat during the summer season.

Main Characteristics

- It creates a sophisticated building with various luxurious colors.

- It presents a picture with the mirror effect due to the reflection.

- It creates a pleasant indoor environment by appropriately adjusting the amount of visible light that flows in and by blocking partial temperature increases due to direct light.

Major Uses

- Exterior windows of houses, general buildings, high-rise buildings, stores, etc.

- Show window, showcase

- Windows of cars, vehicles, and ships

Manufacturing Method

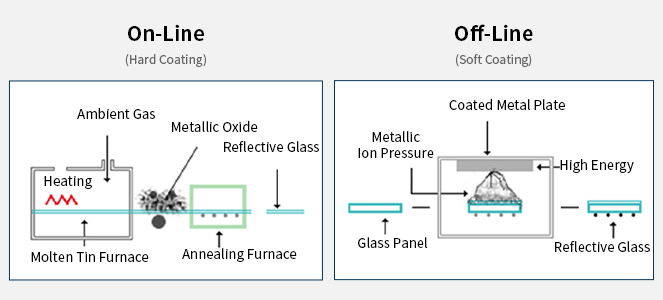

Although coating techniques for sheet glass surfaces are very diverse, the manufacturing methods currently used can be largely divided into Pyrolytic Coating and the Ion Sputtering Process.

Pyrolytic Coating

It is commonly used for hard coating and sprays pyrolytic organometallic materials during the sheet glass manufacturing process at glass surface temperatures between 370°C and 650°C. The material in a metallic molecular state that is decomposed at this time forms a thin film on the glass surface.

Ion Sputtering

It is commonly used for soft coating and it is a manufacturing method in which the surface of the coating metal target is hit with high-energy ions on a cooled glass substrate. This results in small metal particles in an atomic state being separated and deposited on the surface of the glass substrate that was placed below it.

| Classification | On-Line | Off-Line |

|---|---|---|

| Overview | The process in which continuous production without interruption is carried out by coating during the float manufacturing process | The process of transferring manufactured glass to a separate coating facility, then cutting and coating it to the ordered specification. |

| Coating method | Hard Coating | Soft Coating |

| Manufacturing method | Pyrolytic Coating | Ion Sputtering |

| Bonding Method | Chemical Bonding | Physical Bonding |

| Manufacturing Process | A coating method in which metal chemical material is sprayed on the surface of sol state glass at about 370~650℃ which was drawn from the Tin Bath during the glass production process. This material is pyrolyzed by the heat of the glass and coats the glass | It is a technique in which the surface of the coating metal target is hit with high-energy ions on a cooled glass substrate. This results in small metal particles in an atomic state being separated and deposited on the surface of the glass substrate that was placed below it. |

Note

- Since poor cutting can cause thermal breakage, the glass must be clean cut.

- Do not paint or attach paper, tape, film paper, etc. to the glass surface since there is a risk of thermal breakage.

- Please avoid attaching a dark curtain near the glass since thermal breakage can occur.

- Since thermal breakage can occur because coated glass has a high solar heat absorption rate, thermal breakage must be reviewed in advance.

- Secure sufficient gap between the glass and the window. (Accurate construction of the back-up material and the setting block)

- Make sure to cut with the side to be coated facing upwards.

- Do not mark the side to be coated with chalks or marking pens.

- Care must be taken to avoid contact with acids or alkaline materials.

- Care must be taken to avoid rubbing or scratching the side to be coated.

- Do not let the wind from an air conditioning unit directly reach the glass.

- When manufacturing double-layer glass, make sure that the side to be coated is located in the air layer.

- Construct so that the side to be coated is located on side #2.

- When manufacturing and constructing with double-layer glass, the glass surface may become slightly deformed by the change in temperature and pressure of the sealed air layer. However, this is a natural phenomenon that is caused by a difference with the external temperature and pressure and it is not due to a manufacturing or constructi on defect.

Production Specification

| Item | Thickness (mm) | Maximum Size (mm) |

|---|---|---|

| Reflective Glass | 6 | 2,438 x 3,600 |