- Since poor cutting can cause thermal breakage, the glass must be clean cut.

- Do not paint or attach paper, tape, film paper, etc. to the glass surface since there is a risk of thermal breakage.

- Please avoid attaching a dark curtain near the glass since thermal breakage can occur.

- Since thermal breakage can occur because coated glass has a high solar heat absorption rate, thermal breakage must be reviewed in advance.

- Secure sufficient gap between the glass and the window. (Accurate construction of the back-up material and the setting block)

- Make sure to cut with the side to be coated facing upwards.

- Do not mark the side to be coated with chalks or marking pens.

- Care must be taken to avoid contact with acids or alkaline materials.

- Care must be taken to avoid rubbing or scratching the side to be coated.

- Do not let the wind from an air conditioning unit directly reach the glass.

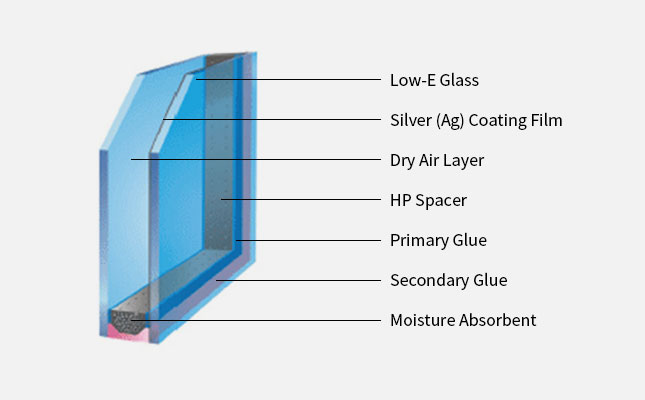

- When manufacturing double-layer glass, make sure that the side to be coated is located in the air layer.

- Construct so that the side to be coated is located on side #3 for ordinary coated glass and side #2 for special coated glass.

- When manufacturing and constructing with double-layer glass, the glass surface may become slightly deformed by the change in temperature and pressure of the sealed air layer. However, this is a natural phenomenon that is caused by a difference with the external temperature and pressure and it is not due to a manufacturing or construction defect.

- Since one side of the glass is coated with a special metal film, a slight interference color may occur depending on the light angle.

- This product cannot be used as single sheet glass and it must be manufactured and used with double layers.

- When using for new and special uses, consult with the technical staff before using it.

- For safety, the structure must be examined for wind pressure resistance, thermal breakage, etc. before use.

Coated Glass

Coated Glass

Low-E GlassLow Emissivity Glass KS L 2017

Energy-saving glass! Among the many parts of a building, the window is the place where energy consumption is the highest. Low-E Glass is a product that was developed to save energy efficiently by transmitting solar radiation into the room and preventing heat generated inside from escaping outside through the windows during the winter season.

Main Characteristics

- It saves about 25% in heating bills.

- It presents a picture with the mirror effect due to the reflection.

- Since it is as clear and transparent as uncoated glass, it harmonizes perfectly with any surrounding environment.

- It is an eco-friendly product that saves energy.

Major Uses

- Exterior windows of buildings and high-rise residential and commercial buildings

- Windows of trains, ships, aircrafts

- Building lobbies, large screen windows

Manufacturing Method

Low-E Glass is a product made by coating thin silver (Ag) film on one side of a sheet glass. It has the characteristic of transmitting most of the visible light and reflecting most part of solar heat. It is an excellent product from an energy-saving perspective since it reflects the heat generated inside back inside so that the interior warmth does not escape outside, especially during the winter. The manufacturing method of Low-E Glass is similar to that of the reflective glass and consists of pyrolytic coating and physical vapor deposition method.

Pyrolytic Coating

It is a method in which glass is coated with metal oxides when it comes out from the Tin Bath. When processing for a laminated glass, the side to be coated must face outside.

Physical Vapor Deposition Method

This is a method of coating metal materials by self-discharge. Since the hardness of the side to be coated is weak, it must always be used as double-layer glass.

Note

Production Specification

| Item | Thickness (mm) | Maximum Size (mm) | Minimum size(mm) |

|---|---|---|---|

| Low-E Glass | 5 | 2,438 x 3,600 | - |

| 6 | 2,438 x 3,600 | - | |

| 8 | 2,438 x 3,600 | - |

Main Performance of Low-E Glass

Improved heat insulation property

Indoor lighting effect is outstanding since visible light transmittance is high, and heating costs for the winter season is reduced due to the excellent heat insulation property.

Excellent condensation preventing effect

When combined with double-layer glass, dew formation prevention effect is outstanding since the resulting heat insulation property is about 30% higher than double-layer glass.

Perfect harmony with nature

When combined with double-layer glass, dew formation prevention effect is outstanding since the resulting heat insulation property is about 30% higher than double-layer glass.

Provides a pleasant indoor environment

A pleasant indoor environment is provided by blocking unpleasant cold radiation around the windows during the winter season.